Essential for any Manufacturing or Industrial user.

The “TC” series torque checkers, mounting bracket included, are essential for any manufacturing or industrial tool room that issues torque measurement instruments. They reduce down time in automotive repair shops by allowing in-house checks of torque wrench calibration.

The checkers feature three modes of operations:

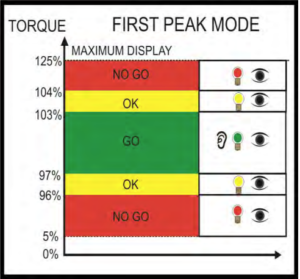

1. Normal Track mode for monitoring applied torque in real time. This is most useful when checking or calibrating electronic, dial or bending beam type wrenches or drivers. 2. Automatic Peak mode captures the maximum torque applied, which is useful for training wrench users to avoid over-torque applications. 3. The First Peak mode is selectable for use in capturing the “click” of mechanical click-type wrenches and drivers even if unintentionally over-driven by the user. An innovative “Go-NoGo” alert indication is active in the First Peak mode for quick identification of clicktype wrench setting. Click accuracy within ±3% shows a green indication within ±4% a yellow indication and greater than ±4% a red indication. See the example diagram.

Intuitive User Interface

A torque Preset function, where the tri-color visual indicator, audible sound and tactile vibration alert, delivers 7 indicators for early warning and over-torque conditions. The large 4-digit LCD display provides Unit selection and instant conversion between “ft-lb”, “in-lb” and “Nm” torque values. The checker battery consists of three conveniently replaceable AAA Alkaline cells that last for over 400 hours of continuous operation. The TC testers are compliant with ISO-6789-2003 and ASME B107.29-2005 (Type I) Standards.

A calibration certificate with National Institute of Standards and Technology (N.I.S.T.) traceability is provided with each tester.